value through

the technology

TECHNOLOGIES

NIKA

NIKA was founded in 2020 as a business consulting company in the supply chain and development of strategic relationships with national and international markets, particularly in the north e of Eastern Europe. To the consolidated sales and networking skills, over time adding an important work of research and development on 3D printing materials and technologies. 3DtechNIKA was born, a new company department specialized in the production of materials 3D printed products and in the supply of innovative solutions for multiple industrial sectors. 3DtechNIKA is an ambitious project, which aims to create extraordinary value through the technology and the unprecedented combination of materials.

3D PRINTING

3D printing is based on a series of processes that make it possible to produce objects by adding the material of which are made up one layer after another. This is why it is also referred to as “additive manufacturing”. Each layer corresponds to a cross section of a 3D model.

What are the advantages of 3D printing?

- Ability to create complex geometries impossible to achieve with traditional manufacturing processes

- Quick realization times

- Maximum precision in the production of prototypes even of small dimensions

- Versatility of use

- High level of customization

- Absence of investment in production equipment

- Creation of colored articles

3D TECHNOLOGIES OF 3DtechNIKA

Multi Jet Fusion technology, developed by HP, represents one of the systems of fastest additive manufacturing on the market, based on layer-by-layer placement of powder on which a fusing agent is deposited. It is characterized by a high degree of precision and repeatability and is suitable for production of robust, long-lasting and dimensionally stable parts, also in series important.

In a specific version of the machine it is also possible to have a complete one range of colors deposited already in the printing phase.

The Fused Deposition Modeling technology is based on the superposition from the bottom to top of layers of heated and extruded thermoplastic filaments. Also FDM technology is characterized by a good degree of precision and repeatability and is suitable for the production of robust, long-lasting and dimensionally stable parts, in limited series.

- Fast 3D printing speed: this printer is 10 times faster than to similar technologies

- Uniform yield: thanks to the detail agent, the 3D printed surfaces are significantly smoother than in other printing technologies

- Material recycling function: HP Jet Fusion 3D printers automatically extract and reuse the waste material

- Produce brightly colored components while maintaining optimal mechanical properties

- Prototype and manufacture thermoplastic functional parts with a very high precision for any type of geometry

- Accelerate design: create, test, and produce multiple iterations of prototypes in the same time it takes to print a single part

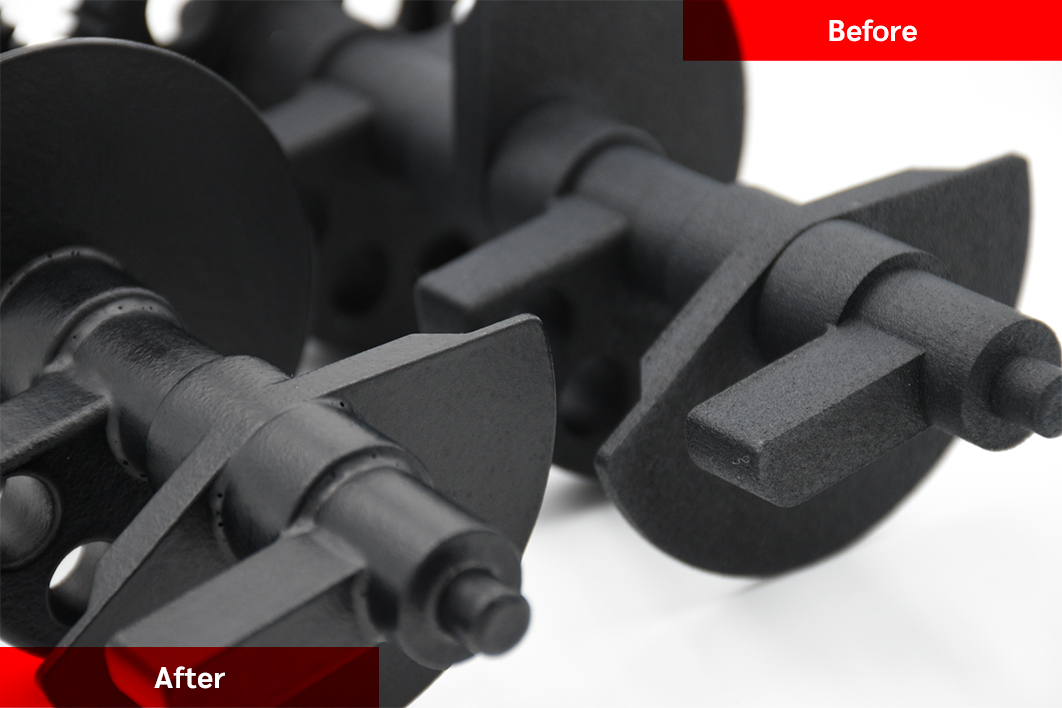

- Mechanical: removing surface porosity makes it more resistant

- Physical: the sealed surface becomes hermetic and does not allow the entry of liquids or gases

- Aesthetic: the surfaces appear shiny and the colors bright

- Hygienic: on the treated surfaces there is a significant reduction of growth and attachment of bacteria. The absence of porosity makes the product made easily sanitized even through washing.

3D TECHNOLOGIES OF 3DtechNIKA

Multi Jet Fusion technology, developed by HP, represents one of the systems of fastest additive manufacturing on the market, based on layer-by-layer placement of powder on which a fusing agent is deposited. It is characterized by a high degree of precision and repeatability and is suitable for production of robust, long-lasting and dimensionally stable parts, also in series important.

In a specific version of the machine it is also possible to have a complete one range of colors deposited already in the printing phase.

The Fused Deposition Modeling technology is based on the superposition from the bottom to top of layers of heated and extruded thermoplastic filaments. Also FDM technology is characterized by a good degree of precision and repeatability and is suitable for the production of robust, long-lasting and dimensionally stable parts, in limited series.

- Fast 3D printing speed: this printer is 10 times faster than to similar technologies

- Uniform yield: thanks to the detail agent, the 3D printed surfaces are significantly smoother than in other printing technologies

- Material recycling function: HP Jet Fusion 3D printers automatically extract and reuse the waste material

- Produce brightly colored components while maintaining optimal mechanical properties

- Prototype and manufacture thermoplastic functional parts with a very high precision for any type of geometry

- Accelerate design: create, test, and produce multiple iterations of prototypes in the same time it takes to print a single part

- Mechanical: removing surface porosity makes it more resistant

- Physical: the sealed surface becomes hermetic and does not allow the entry of liquids or gases

- Aesthetic: the surfaces appear shiny and the colors bright

- Hygienic: on the treated surfaces there is a significant reduction of growth and attachment of bacteria. The absence of porosity makes the product made easily sanitized even through washing.

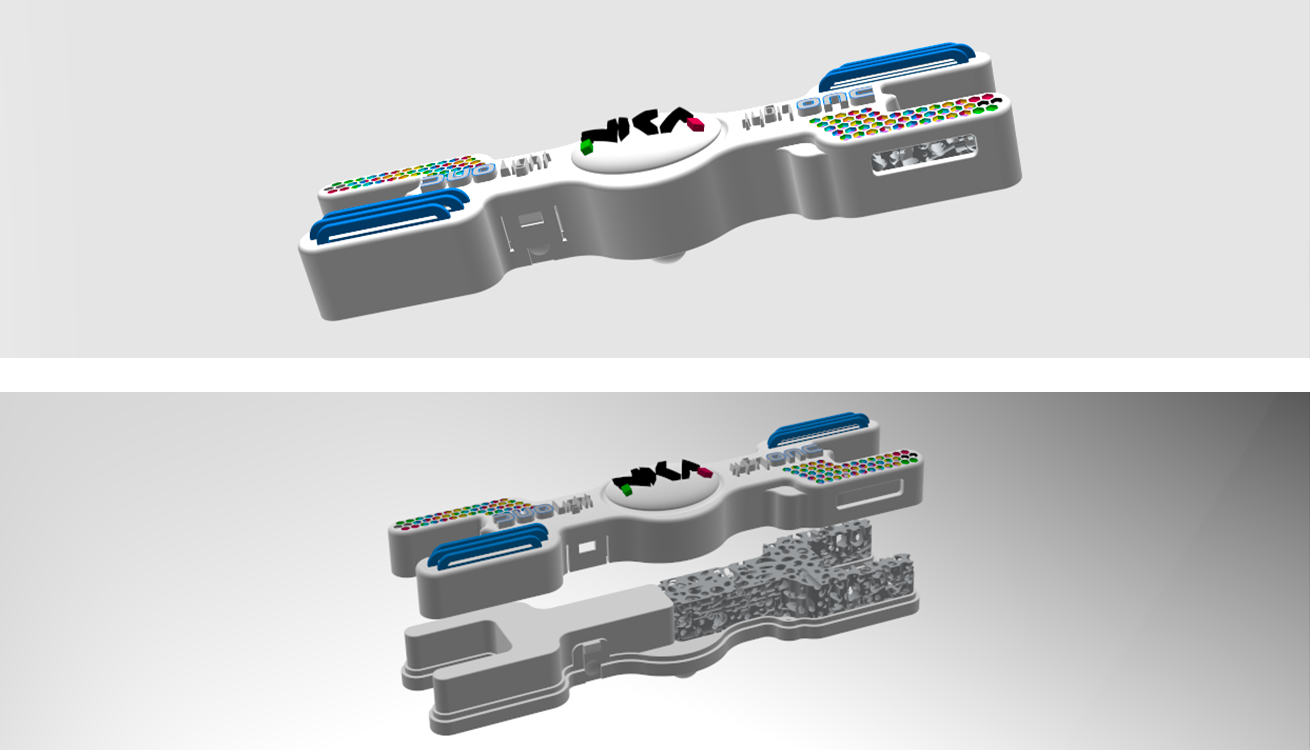

DUOLIGHT: THE HYBRID WHICH UNTIL NOW WAS NOT THERE

From the collaboration between 3DtechNIKA and the MUSP laboratory of the Piacenza Tecnopolo, was born Duolight, an innovative solution that combines 3D printed technopolymers with aluminum foam. From this association derives a hybrid product, which transversely exploit the properties of two materials.

ALUMINUM FOAMS AND POLYMERS FOR 3D PRINTING: THE PROPERTIES

Cellular metals combine into a unique element interesting properties:

2. High specific resistance

3. Resilience (impact protection)

4. Interesting heat exchange properties (heat exchangers)

5. Sound absorption

6. Electrical conductivity

To these characteristics are combined those of the polymers used in the 3D printing

2. Good specific resistance

3. Resilience (impact protection)

4. Thermal insulation

5. Sound absorption

6. Electrical insulation

DUOLIGHT: ONE PRODUCT UNIQUE, 100% INNOVATIVE AND PATENTED

By combining the converging and diverging features of the two technologies into a hybrid product like Duolight, it is possible to achieve results that add up and enhance each other.

This way, it is possible to produce objects:

Washable thanks to the polymer

coating, especially if treated with vapour smoothing

Washable thanks to the polymer

coating, especially if treated with vapour smoothing

Washable thanks to the polymer coating, especially if treated with vapour smoothing

THE ALTERNATIVE TO CARBON, TITANIUM AND SPECIAL ALLOYS OF ALUMINUM

Duolight, together with 3D technology and Vapour Smoothing treatment, represents one innovative solution that can be widely applied in many sectors, such as automotive / motorsport, aerospace, naval, medical, industrial, hobby / collecting. Its qualities and characteristics make it an advantageous alternative for the production of elements normally made of carbon, titanium and special aluminum alloys.

Reference markets and application examples

Radiator supports, auxiliary parts supports, levers for shock absorbers and suspensions, anti-intrusion, intake manifolds

Components for drones, instrumentation mounts on aircraft

Support for rudder moving parts, supports for control instrumentation

Vision system supports

High speed product handling items

Frames of model aircraft and model cars

Contact us

For any information, or doubt, do not hesitate to contact NIKA SRL! Always at your disposal.